Airflow is a critical component in the performance and efficiency of HVAC systems. Proper airflow ensures optimal heat transfer at the evaporator coil and distribution of properly conditioned air throughout the home. The right airflow maintains comfort and air quality, reduces energy consumption, and prevents equipment from overworking or failing prematurely. Diagnosing and resolving airflow issues are a must to ensure optimal system performance.

Tips for Troubleshooting Airflow in a Home’s HVAC System

To troubleshoot airflow issues in an HVAC system, HVAC techs can start with a basic checklist. Assess filters, as dirty or clogged filters can significantly restrict airflow. Inspect the ductwork for any obstructions, leaks, or disconnections that could impede airflow. Vents and registers should be examined to ensure they are open and unobstructed by furniture, curtains, or other objects. The blower motor should be verified for cleanliness and appropriate speed. Evaluate dampers for any closed or improper adjustments that could restrict airflow. Next, we’ll walk through some airflow tests that can help pinpoint system airflow issues.

Conducting a Delta T Test

The Delta T test measures the temperature difference between the return air and the supply air, providing insight into the system’s performance. Comparing the Delta T value to the manufacturer’s specifications can indicate issues such as low refrigerant charge, airflow restrictions, too much airflow, or dirty coils.

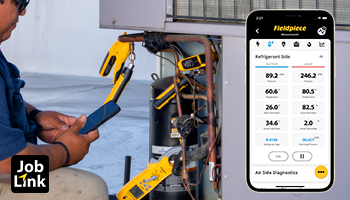

To conduct a Delta T test, technicians need a dual temperature digital thermometer and thermocouples. Highly effective tools for this purpose are the Fieldpiece JL3RH Job Link® System Flex Psychrometer Probes. The JL3RH sends air measurements directly to the Fieldpiece Job Link® System App, allowing for convenient and accurate data collection up to 1000 feet away. The Fieldpiece JL3RH is particularly advantageous for its ability to measure various parameters, including %RH, dry bulb, wet bulb, dew point, and enthalpy, providing a comprehensive view of the system’s performance.

First, install the thermocouples or probes in the return air and supply air ducts as near to the air handler as possible. Turn on the HVAC system and let it run for at least 15 minutes to achieve stabilization. Record both temperatures, calculate the difference between them, and compare to the manufacturer’s specifications.

Conducting a Total External Static Pressure (TESP) Test

TESP measures the total resistance to airflow in the system, which helps identify restrictions or improper installations. To conduct a TESP test, technicians need a dual port manometer, such as the Fieldpiece JL3KM2, static pressure tips, and flexible tubing. Zero the manometer while in ambient pressure with any tubing or probes attached. Specific placements will vary depending on your equipment, but in general target manometer placement will be before the blower and after the coil or heat exchanger. Calculate the TESP by adding the return and supply readings. Comparing the measured TESP to the equipment’s design specifications can indicate high static pressure due to restrictions, such as dirty filters, undersized ductwork, or low static pressure due to duct leaks or low fan speeds.

Conducting a Live CFM Test

Live CFM (cubic feet per minute) testing measures the actual airflow through the system. When assessing airflow efficiency, conducting air balancing or calculating capacity, a vital first step is measuring equipment CFM. To conduct a live CFM test, technicians need an airflow capture hood, or an anemometer such as the Fieldpiece STA2 In-Duct Hot Wire Anemometer. Allow the system to run for at least 15 minutes to stabilize, and ensure all doors and windows are closed to avoid interference from outside air. Measure airflow at the nearest air return to the equipment. If there is more than one return, measure at the return plenum. Comparing the total CFM to the system’s specifications can indicate issues such as duct leaks, blower motor problems, or improper system balancing. While target CFM will vary based on factors such as region or humidity, ensuring it is within the manufacturer’s specifications ensures optimal system performance and comfort for homeowners.

Conclusion

Proper airflow is essential for the efficiency, performance, and longevity of HVAC systems. Technicians must be proficient in troubleshooting airflow issues to maintain system integrity, as some fixes for inefficient airflow can be easily addressed. For more in-depth diagnostic and repair, conducting tests like Delta T, TESP, and live CFM provides comprehensive insights into the system’s performance, ensuring optimal operation and comfort for homeowners.

English

English French

French Spanish

Spanish