Meet the new heart of your job.

Find your nearest distributor to purchase yours today.

Super rugged construction

Data logging

Temperature compensated system tightness test

Sends and receives wireless readings

Protected thermocouple jacks for pipe and outdoor temps

R32 ready

Water resistant (IP54)

A2L Compatible

Designed for Performance

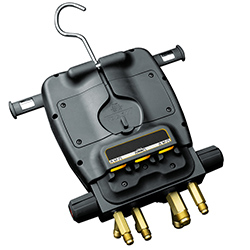

Knowledge, power and experience are packed into the SMAN® Refrigerant 4-valve Manifolds. Years of feedback from A/C and refrigeration specialists is combined with Fieldpiece’s laser focus on continuous improvement to bring you the toughest, most advanced digital refrigerant manifold on the market.

From the extremely rugged overmold casing, reinforced hook, and hermetically sealed sight glass, to the wireless capabilities, data logging, and tightness test, the SM480V is built so you can do your job easier, faster and better.

Simply Strong

The SM480V 4-valve Manifold is simply strong. The heavy duty casing, reinforced hook, water resistance, impact resistant screen, strategically placed thermocouple ports, and hermetically sealed sig ht glass, all ensure the SMANs are ready to withstand the rigors of field use.

ht glass, all ensure the SMANs are ready to withstand the rigors of field use.

Packed with Knowledge

The SM480V is designed to work the way you do with advanced features to streamline your job and provide your customers with the answers they need.

Data Logging

• Stores up to 9 jobs internally

• Easy download via USB port

• Displays % free storage space before logging begins

• Logs up to 7 days (168 continuous hours)

Tightness Test

• Check for leaks after repairs or installations

• View pressure differential over time

• Timer tracks duration of test

• Temperature compensated with SL temp to avoid false positives

Customizable

• Adjust auto power off duration

• Adjust back light duration

• Set high and low vacuum alarms

• Select each unit of measurement individually

Receives Wireless Measurements

Add Job Link Tools to your arsenal and get live readings directly on the SMAN manifold screen from the Job Link Psychrometers (JL3RH), Job Link Pipe Clamps (JL3PC), and SR47 Refrigerant Scale. Place pipe clamps in the perfect location. Monitor and record live refrigerant usage for precise recovery, charging, and documentation.View live air measurements and calculations while making adjustments.

Increase Professionalism with Job Link® System App

Streamline and simplify your call even further with the Job Link System App. See your measurements up to 1000’ away on your mobile device. Document your work and provide professional reports, including refrigerant weight usage, by simply connecting to the Job Link System app. Helps to reduce call-backs and increase profits.

• View measurements on SMAN and/or in Job Link App

• Monitor and record refrigerant weight

• Direct 1000’ wireless range (no transmitter needed)

The SM480V is also available in Europe and is R32 ready. Model number SM480VINT. For specifications, please click here.

Includes:

Specifications

SM480V - SMAN™ Kältemittelverteiler und mikrometergenaues Unterdruckmessgerät (4 Anschlüsse)

SM480V - Manómetro digital con vacuómetro SMAN™ e indicador micrométrico (cuatro puertos)

SM480V - Manifold de fluide frigorigène + microvacuomètre SMAN™ (4 ports)

SM480V - Gruppo manometrico per refrigeranti a 4 porte e vacuometro con lettura in micron SMAN™

SM480V - Manifold de refrigerante SMAN™ + Vacuômetro (4 Portas)

SM480V—Wireless 4-Port SMAN™ Refrigerant Manifold and Micron Gauge v24

SM480VINT—Wireless 4-Port SMAN™ Refrigerant Manifold and Micron Gauge v26

The moisture inside the system is still boiling off and is no longer being taken out or compensated for by the vacuum pump

There could be oil that is holding moisture inside either the hose leading to the manifold or inside the block of the manifold

Microns being inaccurate is a sign of oil holding moisture either inside the block of the manifold, In the hoses or the oil in your vacuum pump needs to be changed.

Clean sensor periodically with rubbing alcohol

You have isolated the micron gauge from the system, you are now only reading what is inside your manifold and hose to vacuum pump

Push target superheat on manifold. Select IDWB or ODDB using the up and down arrows. Hold enter until digit flashes, use up and down arrow to select number, push enter to go to next digit.

You may have a negative degree of superheat or subcooling

Subcooling is not working-

1)Plug in thermocouple into LLT port and change refrigerant to R113 to check to see if the manifold calculates subcooling.

Superheat is not working-

1)Plug in thermocouple into LLT port and change refrigerant to R407F to check to see if the manifold calculates superheat.

Cleaning the Micron Sensor Over time, the vacuum sensor of the SMAN may become contaminated with dirt, oil, and other contaminants from pulling vacuums.

Using an Ice bath approximately 70% ice 30% water, place the pipe clamp in the ice water and stir for approx. 15-20 seconds. Below the SLT and LLT port there is a black screw that can be turned clockwise to bring the temp up and counterclockwise to bring the temp down.

Manifold needs to finish searching and needs to be reset by pushing the sync button and waiting for the manifold the manifold to no longer searching for a signal.

Your manifold does not have a wireless device synced transmitting your wetbulb temp.

The weird looking numbers stand for “no signal” (NSG)

All of our products have a 1 year warranty from date of purchase.

When charging a system, recovering or discharging your hoses, ESD (electrostatic discharge) is created and can give out enough electricity to shock you. Proper grounding will avoid this issue

– Advanced Calibration

Both pressure sensors should read “GOOD”

Yes. For use only by qualified and certified technicians in the safe use, handling, and transporting of refrigerants. Please refer to flammable refrigerant safety guides, regional codes and legislation for more information.