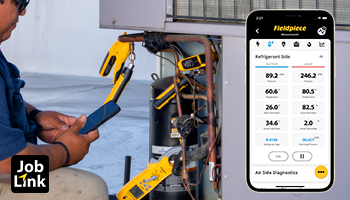

The HVACR industry thrives on efficiency, precision and reliability. In such a demanding field, having the right tools can make all the difference. Fieldpiece Instruments’ Job Link® System App stands out as a comprehensive solution, providing HVACR professionals with the tools they need to excel in their jobs. We’ll explore the many benefits of the Job Link System and the experiences of four HVACR professionals – James Farmer, Vinny Lopez, Luis Rios and Grant Lloyd –on how the ecosystem has transformed their daily workflows.

Maximizing Client Trust with Real-Time Data: James Farmer

James Farmer, an HVACR technician from New Bern, North Carolina, has been using the Job Link System App for several years. His favorite feature is the Live Measurements feature, which allows him to provide real-time data to his clients. Farmer shared a compelling story about a hospital with extremely dirty evaporator coils. By using the Job Link System App, he was able to show real-time improvements in the system’s performance after cleaning the coils. “The customer was impressed,” Farmer recalls. “I sent data and insights in real-time via email, which significantly enhanced my credibility.”

For Farmer, the ability to share detailed reports with clients not only helps in gaining their trust but also in demonstrating the value and transparency of his work. “Clients love the fact that I can send them screenshots showing changes in pressures and temperatures. It shows that I’m not just a technician who fixes something and leaves. I provide information on how and why these changes matter, giving customers that extra sense of security and assurance.”

Streamlining Workflow with Customizable Features: Vinny Lopez

Vinny Lopez, who owns his HVACR business in Waller, Texas, has found the Job Link Pro version indispensable. He uses it to create and manage new jobs and customers, which has significantly improved his workflow. “It comes down to saving time,” Lopez explains. “With several different locations for various clients, I can specialize each job page per location, so each client gets a personalized experience.”

Lopez plans on utilizing the Live Look-In feature, as he believes this will be a game-changer for his business, allowing him to supervise his techs remotely and provide immediate assistance when needed. “Being able to examine jobs in real-time and guide my techs while they’re on-site will improve efficiency and enhance the quality of our service.”

Optimizing Data Management: Luis Rios

Luis Rios, a field support specialist for Daikin Comfort Technologies, works remotely from Little Elm, Texas, and specializes in residential HVACR systems. Rios utilizes the Job Link® Pro subscription to enhance his daily workflows.

Rios particularly values the platform’s data logging and PDF-saving functions. “We use this information for our retrofit projects, tracking data before and after new installation commissioning,” he explains. These features streamline his reporting processes and enhance data accuracy.

Compared to other apps, Rios finds Job Link’s user-friendly interface and detailed reporting capabilities superior. “Job Link is my go-to app because it’s easy to use and provides comprehensive reports,” he says. Additionally, he appreciates the app team’s responsiveness to user feedback, which continually improves its functionality.

Enhancing Business Operations with Comprehensive Tools: Grant Lloyd

Grant Lloyd, from Hamptonville, North Carolina, has been in the HVACR industry since 2020. As a Job Link system user, Lloyd values the comprehensive nature of the Job Link System App. He started with the free version and quickly upgraded to Pro to take advantage of the additional features he knew would be useful on a day-to-day basis. “I liked being able to create customer sites and keep jobs organized in one place,” Lloyd says. “The inspection checklist is also very useful for ensuring my techs complete jobs correctly.”

Lloyd highlights how the Job Link System App has improved his image as a reliable and knowledgeable technician. “Using Fieldpiece tools and the Job Link System App shows clients that I’m serious about providing top-notch service. The app’s ease of use and reliability set me apart from the competition.”

Testimonials from HVACR pros like James Farmer, Vinny Lopez, Luis Rios and Grant Lloyd underscore the significant impact that Fieldpiece Instruments’ Job Link System App has on HVACR professionals’ workflows. From real-time data sharing and detailed reporting to customizable job management and user-friendly interfaces, the Job Link system offers invaluable tools that enhance efficiency, reliability and client trust. Whether you’re a technician or a business owner, the Job Link System is designed to help you excel in the HVACR industry. Explore the different subscription tiers—Free, Pro and Pro+—to find the best fit for your needs and take your HVACR services to the next level.

English

English French

French Spanish

Spanish