Now that we’re in the middle of heating season, we bet you’re making more and more service calls for malfunctioning or under-performing furnaces. During these calls, it’s important to make sure that the furnace pressure switch is functioning as intended.

The furnace pressure switch opens and closes to prevent harmful combustion gases from entering the living space and to prevent furnace fires and potential explosions. An elastomeric diaphragm within the switch remains open when the furnace is off. When the furnace is turned on and functioning correctly, the diaphragm operates under the correct pressure created by the draft inducer motor. This completes an electrical circuit that allows the furnace to ignite for the heating cycle. If the pressure conditions are outside of manufacturer specifications the switch will open to initiate a shut-down to prevent the creation of an unsafe environment for residents and technicians.

When examining a pressure switch, start by using a CO detector to check for harmful gases to ensure you can work safely. Then, run the furnace through its cycle. If you notice erratic ignition cycling when there is a call for heat from the thermostat, that may indicate that the diaphragm or the pressure switch is old and could need replacing. Also, check to make sure that the furnace is properly vented.

If the furnace tries to cycle but stops during start-up and then shuts down, it may be because of a faulty pressure switch. In this case, check for a clogged hose port, a blockage in the flue, corrosion or debris blocking the switch. A bad spring could also be the culprit. All of these should be examined.

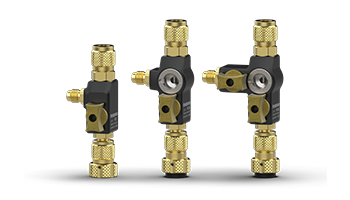

To test a pressure switch, an ideal tool is the Fieldpiece SDMN6 Manometer Dual Port w/ Pressure Switch Tester. This versatile manometer allows a tech to use the ports to quickly connect to the switch while it’s still in place, confirm that it’s operating correctly and even verify it is performing within manufacturer specifications.

When a pressure switch is faulty and requires replacement, a good piece of advice is to keep a supply of universal pressure switches in the truck. This quickly helps get a furnace back to operating properly. When replacing a faulty switch with a universal switch, it’s best practice to notify the property owner. Given the importance of the proper fit and setting of a pressure switch, some owners may be willing to wait for the procurement of an OEM part for additional piece of mind, or even request a future update from a universal switch to the OEM. This will allow for their system to be operable until a follow-up call can be made with the requested pressure switch.

The pressure switch is an important piece of every heating system and knowing how to examine, test, calibrate and replace them is a critical job for techs and the Fieldpiece SDMN6 is the best tool for the job. Learn more about the SDMN6 at Fieldpiece.com.

English

English French

French Spanish

Spanish