A career path in HVACR is a rewarding experience, especially if you take the time to invest in yourself. Going through a postsecondary education; an apprenticeship to learn the ins and outs of the HVACR industry; or an employment opportunity that teaches you along the way is the first step toward success; but to get the most out of your career as an HVACR professional, you’ll want to take a few extra steps to enable a more fulfilling future.

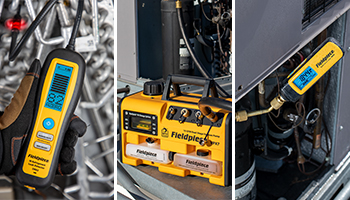

Don’t Sell Yourself Short. Invest in Quality Tools.

Getting started as an HVACR technician can be an expensive undertaking as you quickly realize the person providing your HVACR tools (more often than not) is YOU. Yes, while there are some companies that provide tools or reimburse you for tool expenses, often you need to budget for your own tools. This is a big reason those starting off tend to lean toward purchasing inexpensive products in hopes of saving money.

The problem is they end up needing to purchase replacement tools more often than those that invest in quality the first time around. While finding the best bargain sounds like a good option when you are just getting started, the idea of tools breaking or not functioning properly may sound a little worse. Plus, you’ll want the bells and whistles soon. While just “the basics” may suffice on day-one of your career; in time, most technicians realize how much faster and more efficiently they can work with tools that do a bit more heavy lifting.

Purchasing durable HVACR tools that hold up to the test of time and withstand frequent drops and the rigors of field use, often means setting aside a slightly higher initial tool investment budget. Luckily student discount programs can help offset these costs.

And just because you’re new to the trade does not mean you need to buy “beginner” tools. It’s best to buy quality tools that provide assurance on the job and serve you well for the long haul versus purchasing more inexpensive, poorer quality tools that cost you more in the long run.

With this in mind, prioritize the tools you know you are going to use often, and whenever possible, purchase them through HVACR tool company program discounts. Consider this an investment in yourself.

Invest in Your Knowledge and Skillset.

Your initial education teaches you the basics of how to install, repair, maintain and troubleshoot systems whether in the commercial, residential or refrigeration space, but you’ll also learn something new on the job every day.

The very best HVACR professionals, or #MastersoftheTrade are always working to understand new technologies, tools and methods for completing a job. That’s why continuing education programs that enhance your HVACR knowledge and skillset— many of which are available free and online and offer NATE credits – can help you stay ahead of the HVACR curve.

If you find yourself with spare time while waiting for measurements or between jobs, take advantage of programs that serve to bolster your knowledge. And of course, always keep in mind the quality of your tools. Never question an investment in you – whether it is a matter of time or money, you and your future are worth it. Every HVACR professional deserves the best – even when they’re just getting started.

Visit fieldpiece.com/hvacrstudentresources today to learn more.

English

English French

French Spanish

Spanish